Washing and

filling KEGs

- Keg washer and filler in one machine

- Full stainless steel design

- Small footprint

- Available to work with any coupler A, D, G, M, S, U

About KWF

Our keg washers and fillers are available in manual and full automatic version. Simple but strong machines ready to work imidiatelly.

KEG most often used package in the world for beer made from stainless steel or aluminum. In past was this type of package made from wood and used for storage nails, gunpowder and a variety of liquids. In this age it is very popular for storage beer, sodas, cider or wine and its transport. Such a beverages are generally kept in the keg under pressure. A keg has a single opening on one end, called a "bung." A tube called a "spear" extends from the opening to the other end. There is a self-closing valve that is opened by the coupling fitting which is attached when the keg is tapped. There is also an opening at the top of the spear that allows gas (usually carbon dioxide) to drive the beer out of the keg. The coupling fitting has one or two valves that control the flow of beer out of and gas into the keg. The keg must be in the upright position, that is, with the opening on top for the beer to be dispensed. Kegs can be contrasted to casks, which have two or more openings and no spear. Most major breweries now use internally speared kegs.

Historically a beer barrel was a standard size of 50 gallons, as opposed to a wine barrel at 32 gallons, or an oil barrel at 42 gallons. Over the years barrel sizes have evolved and breweries throughout the world use different sized containers. Even when the content capacity of two kegs are equal—e.g. metricized to 50 liters the keg shape and keg tap system may differ greatly

In the world are used several types of KEGs divided depending on country and its common system.

- U.S. keg sizes (1⁄2 barrels of 15.5 gallons, 1⁄4 barrels of 7.75 gallons, and 1⁄6 barrels of 5.17 gallons)

- DIN keg and EURO keg (same volumes 20,25,30 and 50 liters but different dimensions – diameter/height)

Special types of KEGs

- Cornelius kegs

- Mini kegs 5 L

- Beer balls

- One way kegs (Petainers or Key-Kegs)

OUR PRODUCTS

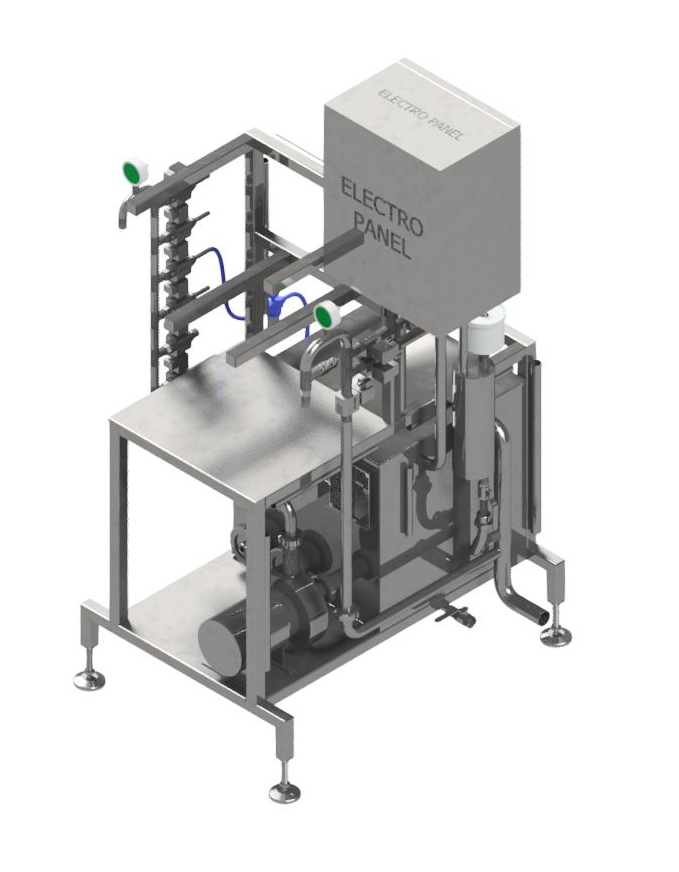

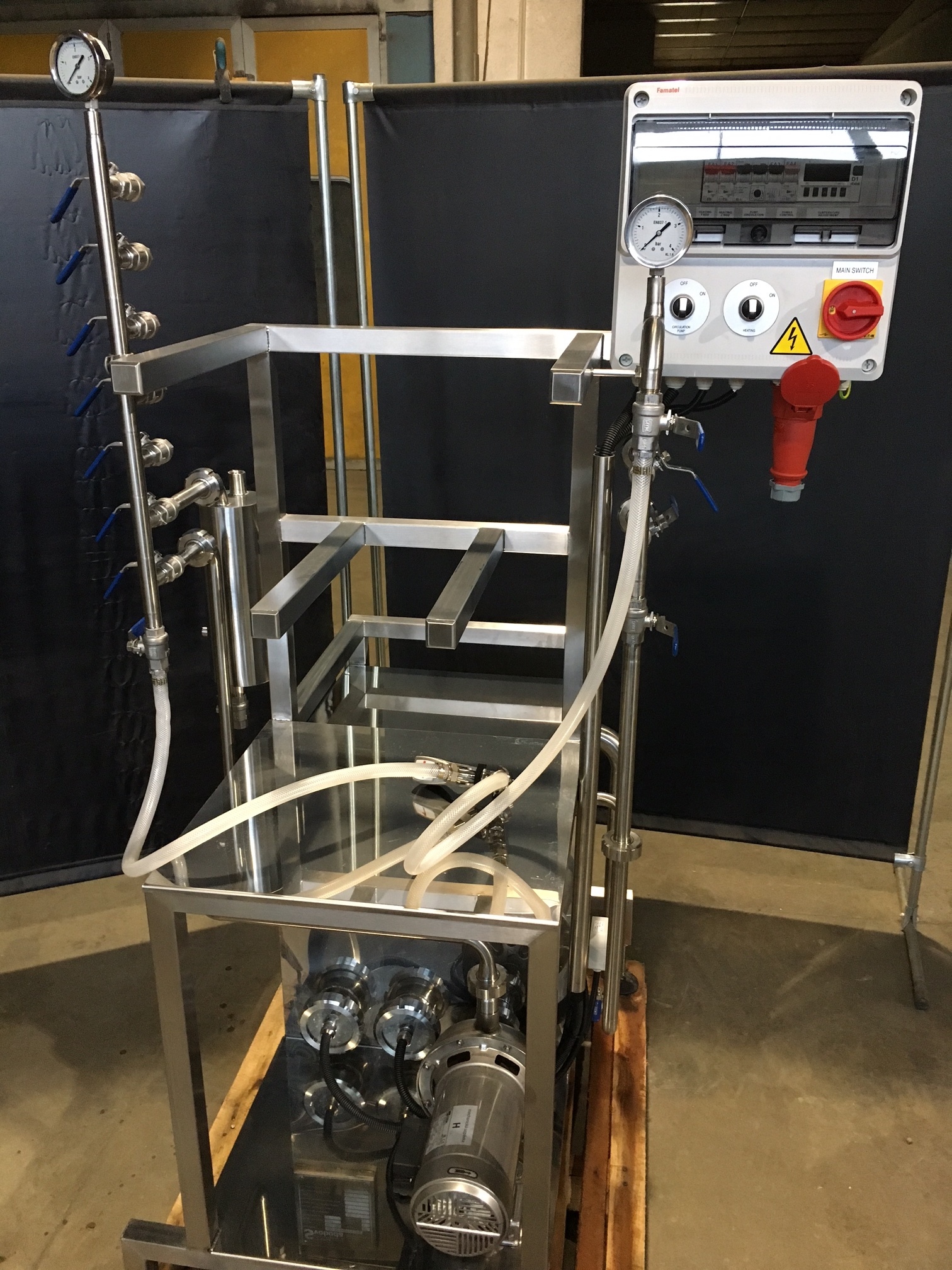

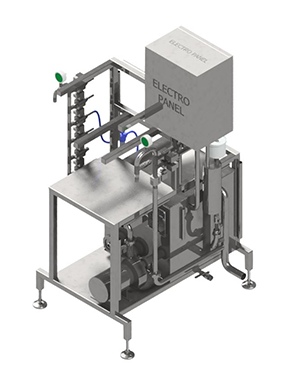

Keg washer and filler KWF-10

KWF-10 is full stainless steel (AISI 304) machine designed for cleaning and filling KEGs of volumes 15 up to 50 liters. Machine is equipped with storage tank for sanitation solution, heating spirals, pump and operation panel for controlling temperature and pump. KWF-10 can clean and sanitize 10 x 50 liter KEGs per hour, in combination with filling the performance is 7 x 50 liter KEGs per hour.

- Emptying of the beer keg

- Depressurization of the keg

- Flushing of the keg with cold water

- Flushing of the keg with sanitizing solution

- Flushing of the keg with cold water

- Steam sterilization of inside of the keg

- Filling of the keg with CO2

- Filling of the keg with beer

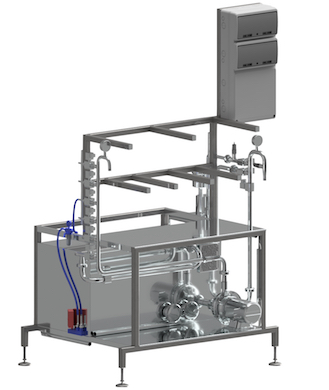

Keg washer and filler KWF-30/A

KWF-30/A is full stainless steel (AISI 304) machine designed for cleaning and filling KEGs of volumes 15, 30 and 50 liters. Machine is equipped with storage tank for sanitation solution, heating spirals, pump and operation PLC panel.

- Emptying of the beer keg

- Depressurization of the keg

- Flushing of the keg with cold water

- Flushing of the keg with sanitizing solution

- Flushing of the keg with cold water

- Steam sterilization of inside of the keg

- Filling of the keg with CO2

- Filling of the keg with beer

Keg filler for mini party kegs of 5 liters volume PKF20

Simple manual equipped with filling needle pressed to keg by moving handle. On the bottom is draining plate. Made from AISI 304.

Keg washer and filler KWF-10

KWF-10 is full stainless steel (AISI 304) machine designed for cleaning and filling KEGs of volumes 15 up to 50 liters. Machine is equipped with storage tank for sanitation solution, heating spirals, pump and operation panel for controlling temperature and pump. KWF-10 can clean and sanitize 10 x 50 liter KEGs per hour, in combination with filling the performance is 7 x 50 liter KEGs per hour.

- Emptying of the beer keg

- Depressurization of the keg

- Flushing of the keg with cold water

- Flushing of the keg with sanitizing solution

- Flushing of the keg with cold water

- Steam sterilization of inside of the keg

- Filling of the keg with CO2

- Filling of the keg with beer

Our machines are able to clean any size of keg with any type of coupling fitting. Nevermind if you are using most common types like A, M and S or D, G and U, we can supply the washer/filler for you with necessary type you need.

References

Our quality work is verified by maximal customer satisfaction in many European countries.

Contact us

For non-binding offer please contact us on:

Company INOX Processing – Milan Svoboda is following highest standards and norms for effective production and best quality of the products. We follow these authorities: